The Medical Anodizing Process

Medical Anodizing

Medical anodizing apparently means different things to different people, usually based upon what aspect of the medical device industry those people work within. Most of our customers in the medical device manufacturing industry refer to medical anodizing when discussing what we would call titanium anodizing, whether it be color titanium anodizing or AMS 2488 Type II titanium anodizing

Color Medical Anodizing

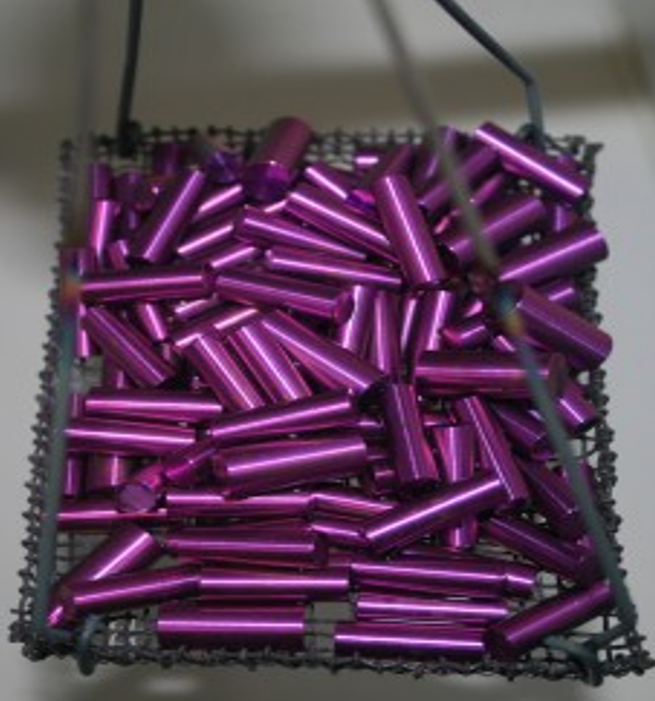

Here is an actual example of color medical anodizing using one of our process lines. Note that it has a few “bells and whistles” that you probably don’t need, but many of our customers are interested in making the process as consistent as possible so they opt for much of what you see here.

The Medical Anodizing Process

The titanium parts shown in the picture on the left (or above) were done using an IPEC Global titanium anodizing line using the system and the “recipes” we provide to our customers when doing the included training session at IPEC Global.

Medical Anodizing Type II Titanium Parts

Many of our customers are also interested in doing a Type II medical anodizing to provide an anti-galling property to the surface of the titanium parts, and the dark gray parts shown in the next picture show some of those parts. Note that the picture shows the parts after the chemical process itself, followed by a blowdown and drying period and then after sandblasting to remove the chalky residue that the anodizing process leaves on the surface. See our article on the type II process for more information about the process itself.

You can see more specific medical anodizing info on color titanium anodizing or type II titanium anodizing by clicking on those links.