How To Anodize Titanium

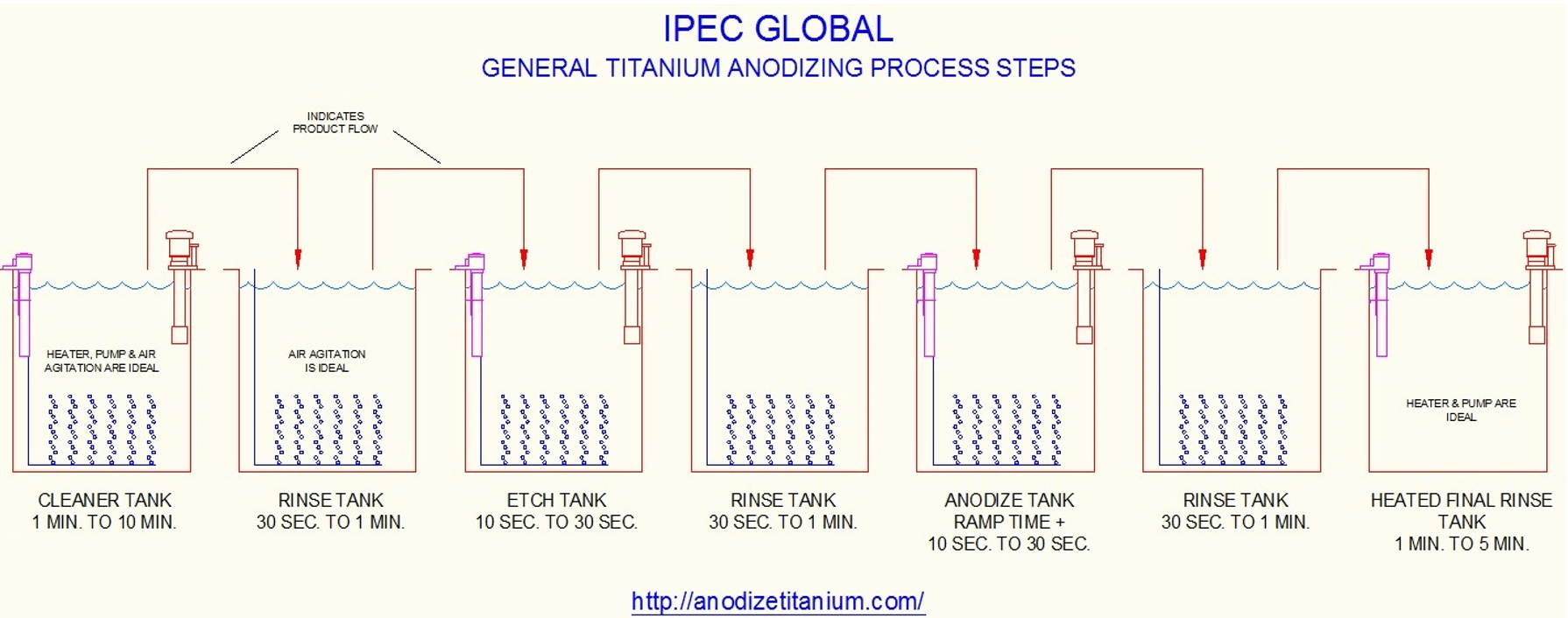

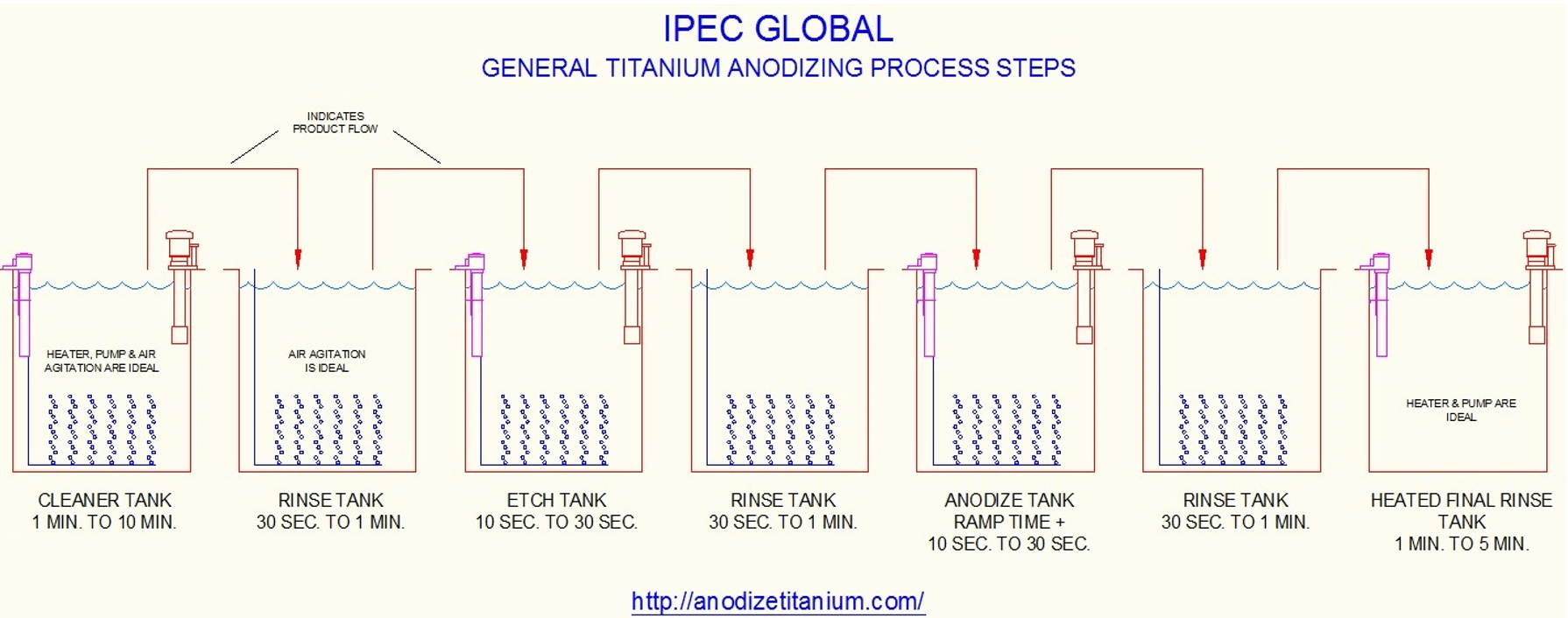

We are often asked for a general description of the process steps to define “how to anodize titanium.” Here is an overview of what a typical industrial titanium anodizing line would involve. Note that we are assuming the parts have already been thoroughly cleaned and either rack-mounted or placed in an appropriate basket or other fixture prior to the chemical processing done here. Here is an overview of the titanium anodizing process:

How to Anodize Titanium for color Anodizing:

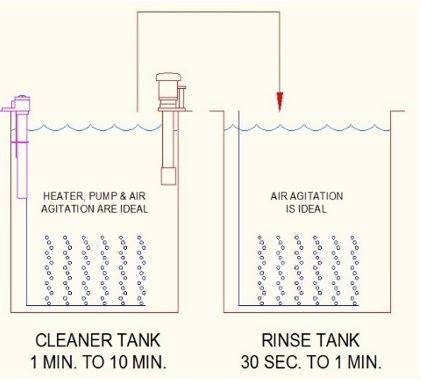

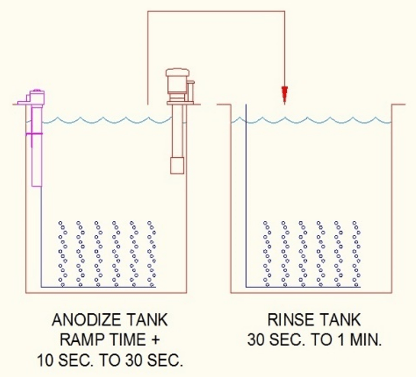

Step 1:

Step 2:

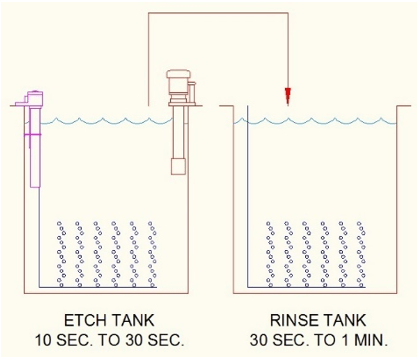

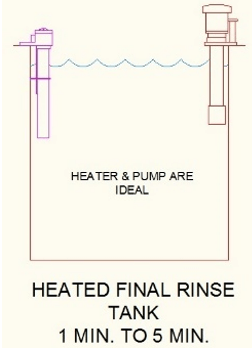

Step 3:

Step 4:

How to Anodize Titanium for Type II

How to anodize titanium with AMS2488 or Type II (sometimes referred to as gray anodizing, conventional titanium anodizing or anti-galling anodic coating) is very similar to the type III color anodizing, except for step 3. Note that the electrolytes (the chemistries in the anodizing tank) are different for type II and type III, and the process times and rectifier parameters are different, but many of our customers use the same IPEC Global titanium anodizing line to do both types.

Instead of step 3 above

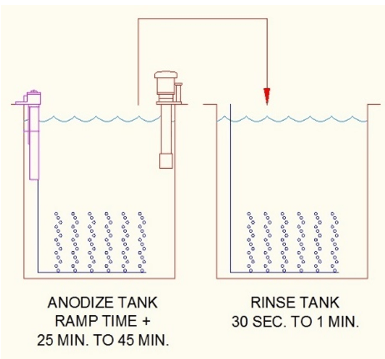

Step 3: Dip two or three times to work any air bubbles out of the parts, then place in the titanium anodize tank. Start the rectifier and let it ramp up to target voltage or amperage. Ramp time should be on the higher side if there are blind holes or recesses where the off-gassing can create a pocket. Vigorous air and solution agitation (if not mechanical agitation too) is required for full, consistent coverage. Once the amperage drops off to zero (approx. 25 min. to 45 min.), pull the parts out of the anodize tank and rinse thoroughly in the following rinse tank. Note that high voltages are present when anodizing, so extreme care should be taken and electrical contacts should not be touched while the power supply is turned on.

Here is the overview of how to anodize titanium for the AMS2488 or Type II Titanium Anodizing Process: