AMS 2488 Type II Titanium Anodizing

AMS 2488 Type II Titanium Anodizing

Type II Titanium Anodizing

There is a lot of interest regarding Type II Titanium Anodizing (per AMS 2488D) and we get a lot of repeated questions as a result.

Will the IPEC Console-style titanium anodizing lines work for either color anodizing or Type II?

The short answer to this is yes, but because the process time and DC current required are so much greater for Type II Titanium Anodizing, we sometimes “nudge” our customers to consider a double anodizing line so they can have the separate chemistries for color anodizing and for Type II anodizing at the same time. If your Type II requirements are high enough, we might even suggest a second rectifier so both processes can be run concurrently and so we can size the rectifier for the Type II anodizing at a lower DC voltage and a higher DC current.

Can IPEC provide the chemical concentrations and operating parameters for the Type II Titanium Anodizing and for the other processes in the line?

Yes- We do provide a list of the parameters for both Type II and color titanium anodizing, including the chemistries used, with the chemical concentrations and some useful troubleshooting information for the process and for the line. Also with the purchase of a titanium anodizing line come the drawings and equipment matrices usually required to pull permits as well as the training to perform the anodizing processes, provided the training is done at IPEC (on-site training is available with the purchase of a titanium anodizing line but for a fee).

Why is sandblasting usually required when doing the type II processing?

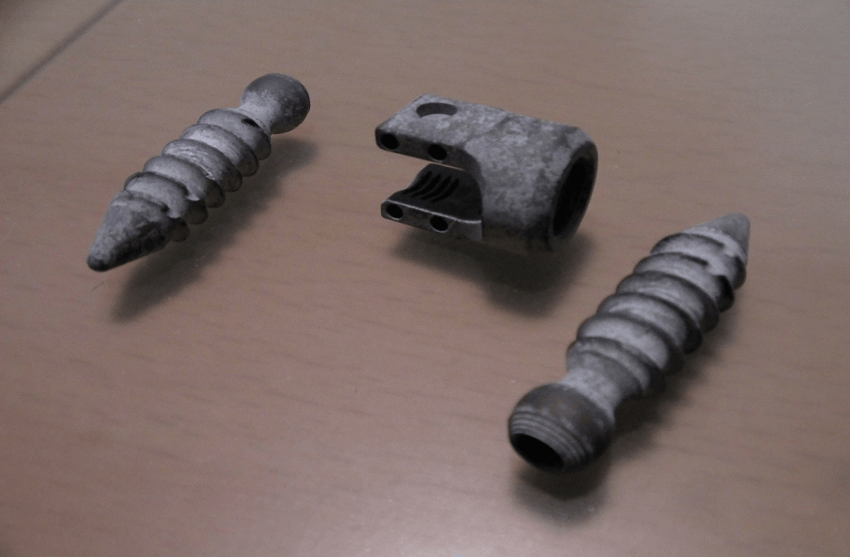

After doing Type II Titanium Anodizing, a powdery residue is left on the parts that may interfere with the coatings anti-galling properties.

Type II Titanium Anodizing before sandblasting to remove powdery residue.

We have customers ask about using vibratory tumblers instead of sandblasting, but we have yet to find a case where it works well enough to eliminate sandblasting. The same goes for using another chemical process to remove the residue. This in no way suggests it can’t be done, but it simply means that none of our customers has found it worthy to pursue an alternative to sandblasting- At least not yet!

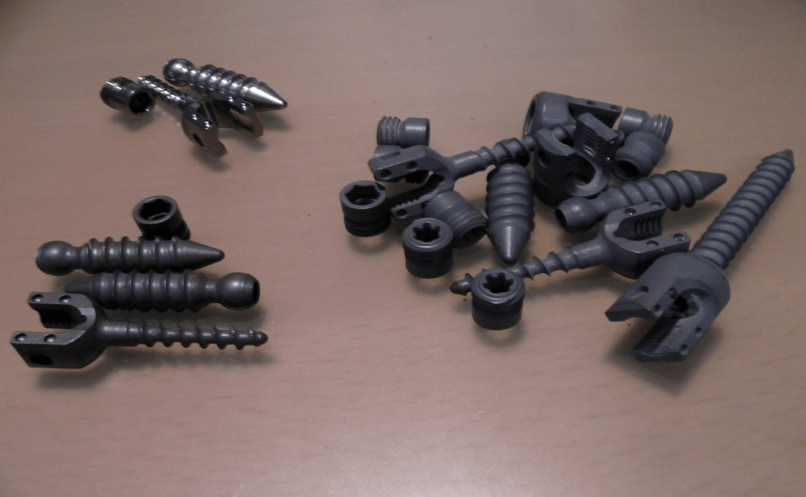

Parts per AMS 2488 Type II Titanium Anodizing, before & after sandblasting

A picture of Type II Titanium Anodizing showing the difference between the parts processed in a vibratory bowl with #16 Silicon Carbide media for 80 minutes (on the right) vs. sandblasting for about 10 seconds each piece (on the bottom left)., with unfinished parts in the top-left.

Type II Titanium Anodizing

As more and more machine shops bring AMS 2488 Type II Titanium Anodizing in-house, we may soon find an alternative to sandblasting the parts after anodizing and drying, but when considering installing a line and looking toward ROI, you should keep the sandblasting step in mind.

IPEC Global can help you decide the proper sized color or Type II Titanium Anodizing line to bring into your facility.